Why Are Fully Embedded Cold Storage Doors Transforming the Future of Temperature-Controlled Facilities?

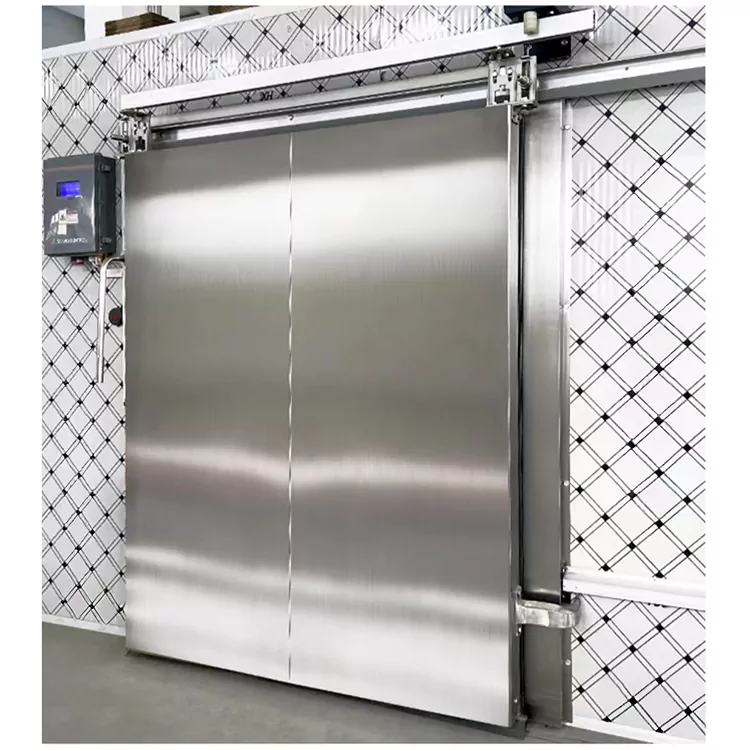

A Fully Embedded Cold Storage Door is a next-generation insulation and sealing solution specifically designed for cold rooms, refrigerated warehouses, and temperature-controlled logistics centers. Unlike traditional cold storage doors that are surface-mounted or externally fixed, a fully embedded door integrates seamlessly into the wall system — creating a unified structure that ensures maximum thermal integrity, energy efficiency, and hygiene.

This design concept addresses one of the most critical challenges in modern cold storage: maintaining consistent internal temperatures with minimal energy loss. As global cold chain logistics expand and sustainability becomes a top priority, the demand for doors that combine durability, insulation, and energy efficiency continues to rise.

In essence, a fully embedded cold storage door is not just a piece of equipment—it is a technological leap that redefines how temperature-controlled environments function. The integration of advanced sealing systems, reinforced panel structures, and intelligent thermal barriers makes it the preferred choice for industries requiring uncompromising precision, such as food processing, pharmaceuticals, and logistics.

Why Choose a Fully Embedded Design?

1. Superior Thermal Efficiency

The embedded installation eliminates gaps between the door frame and the wall panel, which are often the weakest points for temperature leakage. This tight integration minimizes air infiltration and drastically reduces energy consumption.

In comparison, conventional doors typically experience thermal bridging—areas where heat can pass through more easily. Fully embedded cold storage doors are engineered with continuous insulation materials, ensuring that the internal cold air remains stable and uncontaminated.

2. Enhanced Hygiene and Cleanability

For industries adhering to strict hygiene standards, such as food and pharmaceutical production, a smooth, flush-mounted door surface is crucial. The embedded design prevents dust, bacteria, and moisture from accumulating along edges or joints. The absence of protruding parts allows easy cleaning and compliance with HACCP and ISO hygiene standards.

3. Improved Structural Integrity

By embedding the door frame into the wall system, the load distribution becomes more uniform. This reduces structural stress and prolongs both the door’s and the wall’s lifespan. The design also contributes to noise isolation, maintaining a quieter and more controlled environment inside cold rooms.

4. Space Optimization

A fully embedded door saves valuable interior space. With no bulky frame or external hardware interfering, operations such as pallet movement, product stacking, and maintenance become more efficient. For compact facilities, this translates to greater usable storage volume.

5. Aesthetic and Functional Integration

Beyond functionality, the flush-fit design offers a clean and modern look. For commercial cold storage or retail back-end facilities, it provides a professional appearance aligned with corporate aesthetics and operational discipline.

What Makes This Technology So Advanced?

The innovation behind the fully embedded cold storage door lies in its material science and engineering. Every component is purpose-built for extreme temperature retention, operational reliability, and mechanical endurance.

Below is a detailed breakdown of the technical parameters and configurations that define high-performance models in this category:

| Parameter | Specification |

|---|---|

| Door Type | Fully Embedded, Flush-Mounted Cold Storage Door |

| Material Options | Stainless Steel SUS304 / Color-Coated Steel / Galvanized Steel |

| Panel Thickness | 80mm–150mm (customizable based on temperature range) |

| Insulation Material | High-Density Polyurethane Foam (≥ 45 kg/m³) |

| Thermal Conductivity | ≤ 0.024 W/m·K |

| Operating Temperature Range | -45°C to +10°C |

| Sealing System | Multi-Layer EPDM / Silicone Gasket System with Automatic Compression |

| Frame Design | Fully Embedded Frame Integrated into Wall Panel System |

| Opening Options | Manual / Automatic Sliding / Hinged |

| Surface Finish | Smooth, Anti-Corrosion, Hygienic Coating |

| Accessories | Heated Frames (optional), Safety Release Handle, Door Heater Cable |

| Compliance | CE, ISO9001, HACCP Standards |

These parameters reflect the professional-grade specifications required in large-scale refrigerated warehouses, food production lines, and pharmaceutical cold chains. Every unit can be tailored based on site-specific conditions such as humidity level, door size, and operation frequency.

How Does a Fully Embedded Cold Storage Door Improve Operational Efficiency?

Modern facilities face increasing pressure to lower energy costs while meeting environmental targets. The embedded design provides measurable operational advantages that directly impact profitability and sustainability.

-

Energy Cost Reduction

With superior insulation and minimal leakage, embedded doors can reduce energy loss by up to 30–40% compared to traditional designs. The advanced gasket compression system ensures the cold air remains trapped, decreasing compressor runtime. -

Temperature Stability

The stable thermal envelope achieved through embedding allows temperature deviations of less than ±1°C, crucial for sensitive goods such as vaccines, meat, or dairy. -

Maintenance Efficiency

Embedded structures have fewer external components exposed to wear, resulting in lower maintenance costs and longer service intervals. -

Automation Compatibility

Many models support full automation integration—compatible with PLC-controlled or IoT-based facility management systems, enabling real-time monitoring of temperature, humidity, and door cycles. -

Sustainability Benefits

The use of eco-friendly insulation materials and energy-efficient designs aligns with modern green building certifications, such as LEED or BREEAM.

Common Questions About Fully Embedded Cold Storage Doors

Q1: What is the difference between a fully embedded door and a traditional cold room door?

A1: A traditional cold room door is typically surface-mounted, meaning it attaches externally to the cold storage wall. This often leaves gaps that can cause temperature leakage and hygiene challenges. A fully embedded door, however, is integrated directly into the wall panel, forming a seamless junction that improves insulation, cleanliness, and durability.

Q2: Can a fully embedded door be customized for different temperature zones?

A2: Yes. Fully embedded cold storage doors can be designed to suit different cold zones, from chilled (+10°C) to deep freeze (-45°C) environments. The insulation thickness, sealing type, and heating elements are adjustable to meet the specific needs of each facility.

What Are the Future Trends in Cold Storage Door Technology?

As global cold chain logistics evolve, the demand for intelligent, energy-saving, and automation-ready solutions is shaping the next generation of cold storage doors. Here are key trends influencing the industry:

-

Smart Sensor Integration

Embedded doors will increasingly feature built-in sensors for temperature, humidity, and pressure monitoring. Data-driven analytics can predict maintenance needs and optimize refrigeration cycles. -

AI-Driven Energy Management Systems

Facilities will adopt predictive energy control, where smart doors communicate with HVAC systems to minimize unnecessary cooling during door operation. -

Sustainable Material Development

Manufacturers are shifting toward low-carbon steel, bio-based foams, and recyclable coatings to reduce environmental impact. -

Automation and Robotics Compatibility

Cold storage facilities are becoming more automated, requiring doors that respond to machine vision and robotic control systems for smooth logistic operations. -

Enhanced Safety and Compliance Features

Future embedded doors will integrate emergency escape sensors, touchless opening mechanisms, and anti-freeze technologies, ensuring maximum user safety even in sub-zero environments.

The Future of Cold Storage Efficiency with HANYORK

The Fully Embedded Cold Storage Door represents the next era of efficiency, hygiene, and precision in cold storage design. Its seamless integration, superior insulation, and smart-ready compatibility make it indispensable for modern cold chain infrastructure. By minimizing thermal loss, optimizing space, and ensuring compliance with global hygiene standards, this innovation sets a new benchmark for reliability and sustainability.

As cold storage technology continues to evolve, HANYORK remains at the forefront of innovation—delivering advanced, customized, and high-performance door systems tailored for global industries. Whether for large-scale food processing, pharmaceutical logistics, or retail distribution, HANYORK’s fully embedded cold storage doors guarantee long-term efficiency and operational excellence.

For more details, technical consultation, or custom design inquiries, contact us to discover how HANYORK can enhance your facility’s performance and sustainability.

- What Makes a Cold Storage Door Essential for Your Refrigeration Facility?

- What Makes Rock Wool Panel a Game Changer in Modern Construction?

- How Does Cold Storage Refrigeration Equipment Improve Food Safety and Efficiency?

- How Do Evaporator Units Improve Cooling Efficiency?

- Why can't cold storage doors be opened from the inside?

- What are the applications of mobile cold storage?