What Makes Rock Wool Panel a Game Changer in Modern Construction?

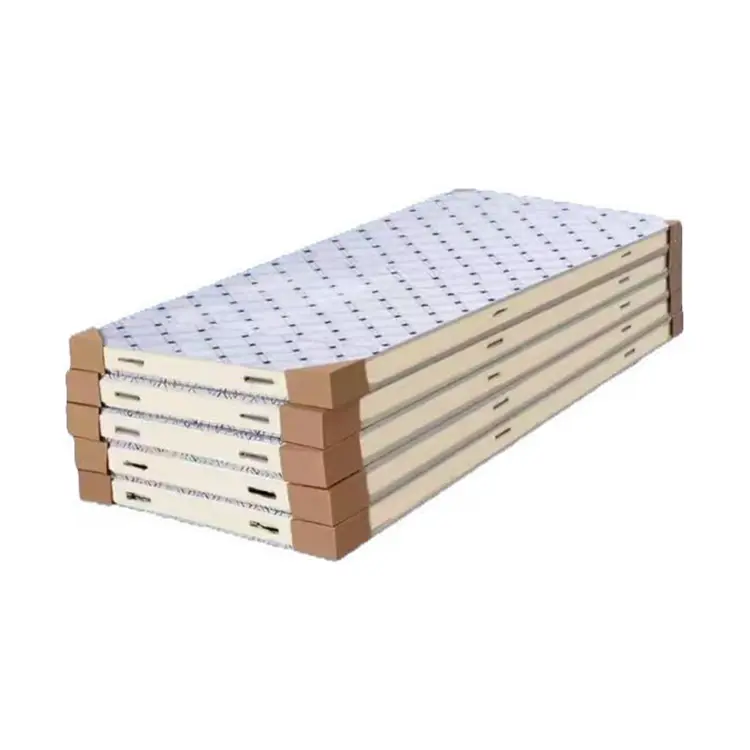

In contemporary architecture and industrial construction, rock wool panels (sometimes referred to as stone wool or mineral wool sandwich panels) have gained rapid traction. At their core, these are composite insulating panels featuring a core made from basalt-based fibrous rock wool, sandwiched between metal facings (e.g. coated steel sheets). Their design aims to combine thermal insulation, fire resistance, acoustic suppression, structural stability, and long-term durability.

What Is a Rock Wool Panel? (and Its Technical Profile)

A rock wool panel is typically a sandwich-structured board composed of:

-

A core of compressed rock wool fibers (basaltic origin)

-

Two metal facings (coated steel, aluminum, etc.) that encapsulate and protect the core

-

Interlocking joints or male/female edges for seamless installation

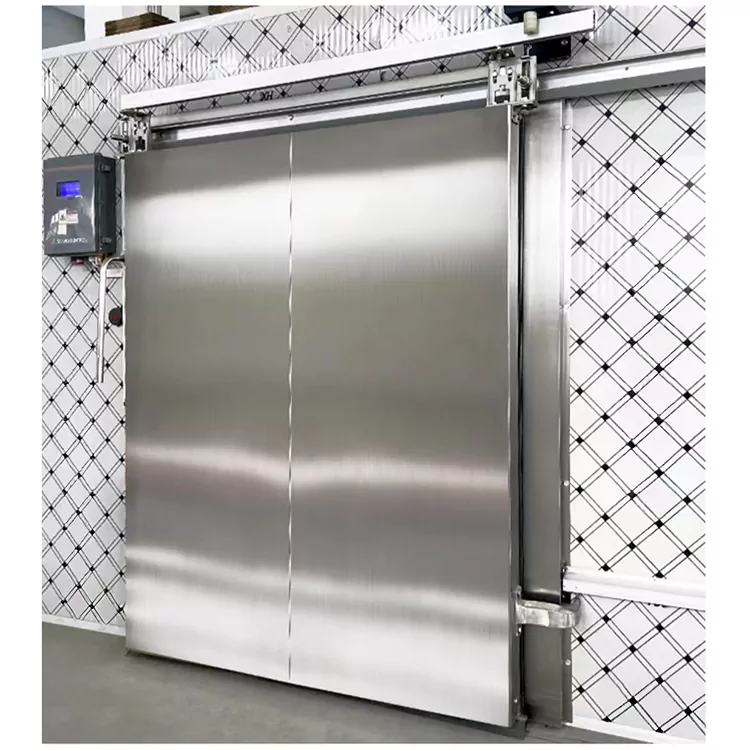

These panels are engineered for insulation, fire protection, and acoustic performance, making them suitable for walls, roofs, partitions, and cold-storage enclosures.

Below is a representative technical specification table for a typical high-performance rock wool panel (customizable ranges noted):

| Parameter | Typical Value or Range | Significance / Notes |

|---|---|---|

| Density (core) | 80 – 200 kg/m³ (sometimes up to 220 kg/m³) | Higher density improves compressive strength and fire resistance |

| Thickness | 50 mm – 200 mm | Selected according to insulation demands and structural constraints |

| Thermal Conductivity (λ) | ≤ 0.035 – 0.043 W/(m·K) | Lower λ means better insulation |

| Fire Resistance | Class A non-combustible; withstands ~1000 °C | Does not burn or release toxic gases |

| Sound Absorption / NRC | 0.75 – 1.0 | Excellent for noise control in partitions |

| Moisture Absorption | < 1% (or ≤ 0.2–0.5%) | Helps prevent mold, corrosion, and degradation |

| Compressive Strength | ≥ 40 kPa (or specified per project) | Ensures structural stability under load |

| Service Life | 25 – 50+ years | Maintains performance over decades |

| Facing Plate Thickness | 0.4 mm – 0.8 mm (coated steel) | Balances durability, weight, and cost |

| Joint Type | Male-female tongue & groove, snap-in, plug-in overlaps | Ensures tight seals and reduces thermal bridging |

These parameters may vary depending on manufacturer, customization, local codes, and project-specific demands. For example, HANYORK’s rock wool panels offer customizable thickness, densities, and surface finishes, with a moisture absorption rate as low as 0.2% and a service life up to 25 years.

Why Choose Rock Wool Panels? (Benefits and Comparative Advantages)

Fire Safety & Non-Combustibility

Rock wool is inherently non-combustible. Unlike foam-based insulation (e.g. PU, PIR, EPS), rock wool won’t ignite or produce toxic smoke under fire exposure. This makes it a strong option for high-risk buildings, façades, high-rise applications, and industrial facilities.

Thermal Efficiency & Energy Savings

The finely fibrous structure traps air at micro-scale, reducing heat transfer. With low thermal conductivity, rock wool panels help maintain indoor temperatures, reduce HVAC loads, and lower energy bills over the life of the building.

Acoustic Insulation

Rock wool panels provide superior sound absorption and dampening, making them ideal for partitions, studios, corridors, hospitals, and offices. Their NRC (Noise Reduction Coefficient) can reach 0.75 or higher depending on thickness/density.

Moisture & Mold Resistance

With proper hydrophobic treatment, rock wool resists moisture uptake (<1%), which helps prevent mold growth, deterioration, and corrosion of metallic facings.

Durability & Longevity

Unlike many organic insulation materials, rock wool does not degrade significantly over time. It remains dimensionally stable, resists pests and rot, and maintains performance for decades.

Versatility & Customization

Panels can be customized in thickness, density, surface finish (flat, embossed, coated), facing material, and joint styles to match architectural and engineering demands.

Competitive Edge vs Alternative Materials

When compared to polyurethane (PU) or EPS panels:

-

Fire performance: rock wool wins decisively (non-combustible vs flammable)

-

Thermal stability at high temp: rock wool maintains integrity under heat stress better

-

Sustainability: rock wool is recyclable and often uses natural basalt and recycled slag.

-

Weight and stiffness trade-off: rock wool panels tend to be heavier, potentially requiring stronger support structures

How Are Rock Wool Panels Installed and Applied?

Design & Specification Stage

-

Assess thermal, structural, and fire requirements per local building codes.

-

Determine optimal thickness, density, and facing type.

-

Plan for joints and overlaps to minimize thermal bridging.

Fabrication & Quality Assurance

-

Rock wool fibers are manufactured (melting basalt, spinning, binding)

-

Compression, bonding, and facing lamination establish final panel

-

Quality checks: density, thermal conductivity, fire rating, moisture absorption

Transportation & Handling

-

Panels should be flat-packed, protected from moisture, and handled carefully to prevent core damage

-

Avoid dragging or impacts on edges

Installation Steps

-

Substrate preparation (flat, clean, leveled).

-

Fixing framework or support members (steel studs, channel rails).

-

Install panels using male-female or tongue-groove joints, snap-in systems, or plug-in overlaps.

-

Seal joints with compatible gasketing or sealants.

-

Secure with mechanical fasteners as designed.

-

Apply finishing elements (flashing, trims, coatings).

Post-installation Inspection

-

Verify joint tightness, absence of gaps

-

Check for flush alignment, no distortions

-

Perform thermal and acoustic testing if required

Maintenance

Minimal maintenance is required; periodic inspections for seal integrity, corrosion of facings, and cleaning are sufficient.

What Are the Common Questions About Rock Wool Panels?

Q1: How thick must a rock wool panel be to meet standard insulation requirements?

A1: The required thickness depends on climate zone, U-value targets, and building envelope design. In many temperate regions, panels between 100 mm and 150 mm of rock wool core are sufficient to achieve U-values in the 0.25–0.35 W/(m²·K) range. In colder climates, thickness may go to 200 mm or more. The density and facing also influence effective performance.

Q2: Can rock wool panels be used in humid or outdoor environments?

A2: Yes, when properly treated and sealed, rock wool panels are suitable for humid and outdoor applications. Hydrophobic additives and moisture barriers are incorporated to limit water uptake. Facings (painted/coated steel) and sealants protect the core. For exterior use, ensure flashing, overlaps, and drainage details are well designed.

Q3: Are rock wool panels more costly than alternatives?

A3: Upfront cost tends to be higher than foam-based insulation, but the advantages in fire safety, durability, and energy savings often justify the investment. Over the lifecycle, savings in maintenance, insurance, energy, and risk mitigation can outweigh the initial premium.

Q4: Does rock wool lose performance over time?

A4: No. Rock wool is dimensionally stable, resists deterioration, and maintains its thermal and acoustic properties over decades when properly installed.

What Trends Are Shaping the Future of Rock Wool Panels?

Demand Growth in Green & Resilient Buildings

With stricter building codes, carbon emission targets, and safety regulations, rock wool panels are increasingly adopted as part of sustainable, resilient architecture.

Enhanced Composite Designs

Innovation is focusing on lighter, stronger, and more easily installed panels — e.g. hybrid cores, prefabricated integrated systems, and thinner high-efficiency versions.

Prefabrication & Modular Construction

As modular building methods gain ground, rock wool panels are becoming components of factory-assembled walls and roof modules, accelerating on-site construction and lowering waste.

Smart & Sensor-Embedded Panels

Future panels may embed sensors (temperature, humidity, structural strain) to monitor building health and energy performance in real time.

Circular Economy & Environmental Optimization

Life-cycle assessments indicate that rock wool’s environmental impact can be further reduced through recycling and optimized binder systems.

Regional Adoption & Market Shifts

Asia-Pacific, Middle East, and emerging economies are projected to drive the greatest growth in rock wool usage, underpinned by construction booms and regulatory push.

Summary & Outlook

Rock wool panels offer a compelling combination of thermal insulation, fire protection, acoustic control, durability, and sustainability. When properly designed and installed, they outperform many insulating alternatives in safety and longevity. As building standards tighten and sustainability becomes non-negotiable, the role of high-performance materials like rock wool panels will only expand.

In this evolving market, the HANYORK brand stands ready with advanced manufacturing capacity, strict quality assurance, and customizable solutions tailored for global needs. To explore how HANYORK rock wool panels can support your next construction, retrofit, or insulated enclosure project — contact us today.

- What Makes a Cold Storage Door Essential for Your Refrigeration Facility?

- Why Are Fully Embedded Cold Storage Doors Transforming the Future of Temperature-Controlled Facilities?

- How Does Cold Storage Refrigeration Equipment Improve Food Safety and Efficiency?

- How Do Evaporator Units Improve Cooling Efficiency?

- Why can't cold storage doors be opened from the inside?

- What are the applications of mobile cold storage?