What Makes a Cold Storage Door Essential for Your Refrigeration Facility?

In today's fast-paced cold chain industry, ensuring your storage environment maintains optimal temperature and energy efficiency is critical. One key component often overlooked is the Cold Storage Door. I often ask myself, why is this door more than just an entryway? And the answer lies in its role in maintaining temperature integrity, reducing energy consumption, and improving overall operational efficiency. At Changzhou Hanyork Refrigeration Equipment Co., Ltd., we specialize in manufacturing Cold Storage Doors that cater to diverse industrial needs, ensuring your perishable goods remain fresh and safe.

Why Should I Invest in a High-Quality Cold Storage Door?

The first thing that comes to mind when considering cold storage solutions is insulation. A well-engineered Cold Storage Door does more than simply separate spaces; it acts as a barrier against external temperature fluctuations, humidity, and contamination. Investing in a high-quality door minimizes energy loss, reduces refrigeration costs, and extends the lifespan of stored products. I often ask myself, can a poorly designed door compromise my entire cold storage system? The answer is a definitive yes. That's why choosing a door with advanced insulation, reliable sealing, and durable construction is critical for every facility.

Key Features of Our Cold Storage Doors

Our Cold Storage Doors are engineered with precision and tailored to meet industrial standards. Below is a summary of the primary technical specifications:

| Parameter | Specification |

|---|---|

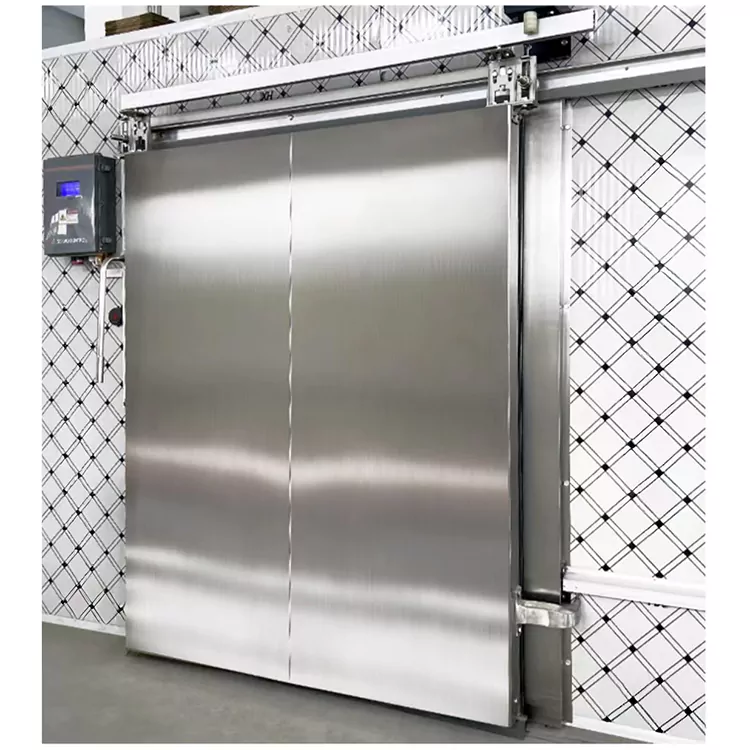

| Door Type | Sliding, Hinged, and Swing Types |

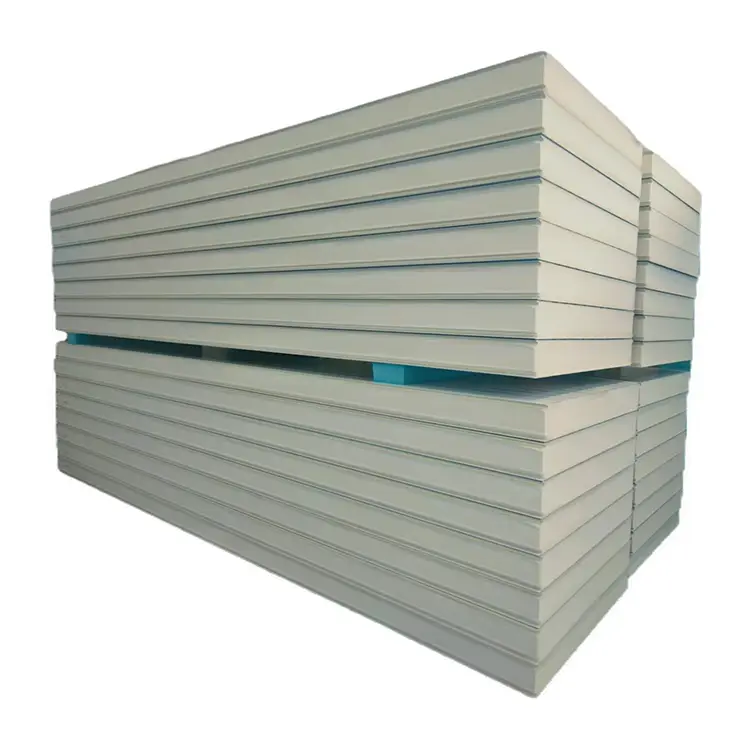

| Insulation Material | High-density PU Foam or PIR |

| Panel Thickness | 80mm, 100mm, 120mm options |

| Surface Material | Galvanized Steel, Stainless Steel |

| Temperature Range | -40°C to +10°C |

| Fire Resistance | Optional, Class B1 Fireproof Panel |

| Door Frame | Powder-coated Steel or Aluminum Alloy |

| Seal Type | Magnetic or Polyurethane Gasket |

| Accessories | Door Handles, Viewing Windows, Safety Alarms |

These parameters ensure our Cold Storage Doors offer excellent thermal insulation, durability, and operational safety. Whether your facility handles frozen foods, pharmaceuticals, or chemicals, our doors provide an optimal environment for long-term storage.

How Does a Cold Storage Door Enhance Energy Efficiency?

I often hear managers ask, how much impact does a Cold Storage Door have on electricity bills? The answer is significant. Poorly insulated or leaky doors can increase energy consumption by up to 20-30%. Our doors are designed with tight seals and advanced insulation panels, reducing cold air loss and maintaining consistent internal temperatures. This not only saves operational costs but also supports sustainable practices by lowering carbon emissions.

Benefits of Advanced Cold Storage Doors

-

Temperature Stability: Prevents warm air infiltration, ensuring products remain at the desired temperature.

-

Durability: High-quality materials resist corrosion and wear in harsh environments.

-

Safety: Equipped with optional alarms and emergency release mechanisms to protect workers.

-

Ease of Operation: Sliding and swing models designed for smooth, low-maintenance operation.

What Types of Cold Storage Doors Are Available?

Understanding the types of Cold Storage Doors can help in selecting the right model for your facility.

-

Sliding Doors: Ideal for large storage rooms; they save space and provide smooth operation.

-

Hinged Doors: Common in smaller cold storage areas; easy to install and maintain.

-

Swing Doors: Allow quick access with optional automatic closing mechanisms for high-traffic areas.

Each type can be customized in size, panel thickness, insulation type, and hardware, ensuring a perfect fit for your facility's needs.

FAQ: Cold Storage Door

Q1: What is the standard insulation thickness for a Cold Storage Door?

A1: Most doors feature panel thickness options of 80mm, 100mm, or 120mm, providing excellent thermal insulation suitable for a range of cold storage applications from -40°C to +10°C.

Q2: Can Cold Storage Doors be customized for large industrial facilities?

A2: Yes, Changzhou Hanyork Refrigeration Equipment Co., Ltd. offers fully customizable doors, including size, type, insulation material, and accessories, ensuring seamless integration with your existing cold storage infrastructure.

Q3: How do Cold Storage Doors contribute to safety?

A3: Our doors include magnetic or polyurethane gaskets for airtight sealing, optional safety alarms, and emergency release handles, reducing risk of accidents while maintaining temperature integrity.

Q4: How often should Cold Storage Doors be maintained?

A4: Regular inspection every 6-12 months is recommended. Check gaskets, hinges, and sliding tracks to ensure optimal performance and prevent energy loss.

How Can I Ensure Longevity for My Cold Storage Door?

Maintenance is key to maximizing the lifespan of your Cold Storage Door. I always advise clients to:

-

Clean panels and seals regularly to prevent dirt accumulation.

-

Inspect mechanical components and lubricate sliding tracks or hinges.

-

Verify insulation integrity to avoid cold air leakage.

Proper maintenance ensures the door remains effective, energy-efficient, and safe for years to come.

Why Choose Changzhou Hanyork Refrigeration Equipment Co., Ltd.?

At Changzhou Hanyork Refrigeration Equipment Co., Ltd., we combine technical expertise with high-quality materials to deliver Cold Storage Doors that meet international standards. Our team understands the critical role doors play in the cold chain industry, and we work closely with clients to provide tailored solutions. By choosing our products, you gain not only superior doors but also reliable support and long-term service.

For inquiries, product customization, or to request a quote, please contact Changzhou Hanyork Refrigeration Equipment Co., Ltd. Our specialists are ready to assist you with the best Cold Storage Door solutions for your facility.

- Why Are Fully Embedded Cold Storage Doors Transforming the Future of Temperature-Controlled Facilities?

- What Makes Rock Wool Panel a Game Changer in Modern Construction?

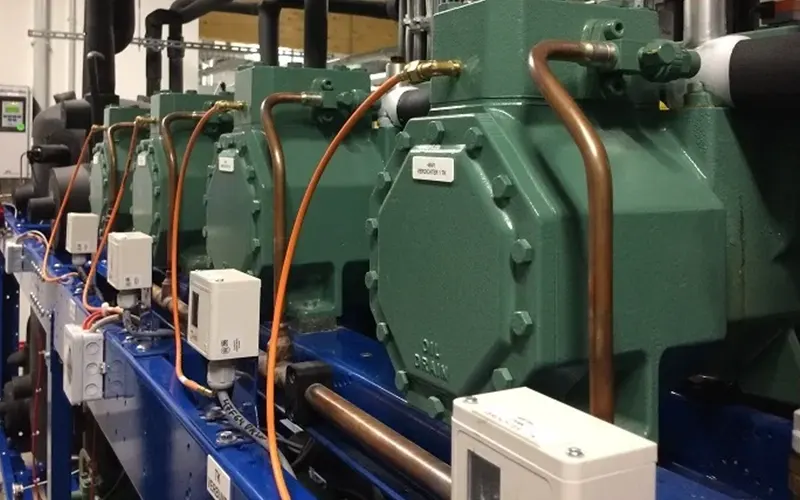

- How Does Cold Storage Refrigeration Equipment Improve Food Safety and Efficiency?

- How Do Evaporator Units Improve Cooling Efficiency?

- Why can't cold storage doors be opened from the inside?

- What are the applications of mobile cold storage?