What is polyurethane foam insulation used for?

Polyurethane foam is a solid polymeric foam based on polyurethane chemistry. As a specialist synthetic material with highly diverse applications, polyurethane foams are primarily used for thermal insulation and as a cushioning material in mattresses, upholstered furniture or as seating in vehicles. Its low density and thermal conductivity combined with its mechanical properties make them excellent thermal and sound insulators, as well as structural and comfort materials.

Polyurethane foams are thermosetting polymers. They cannot be melted and reshaped after initially formed, because the chemical bonds between the molecules in the material are very strong and are not broken down by heating. Once cured and cooled, the material maintains its shape and properties.

Polyurethane foams are the most widely used representatives of thermoset foams. Depending on their cellular structure, they can be classified as open or closed-cell foams. Looking at mechanical properties, there are two main types of polyurethane foam; flexible (soft) and rigid (hard) foams. Generally speaking, flexible polyurethane foams have an open-cell structure where the pores are interconnected, smaller in size and irregularly shaped; contrary to rigid polyurethane foams that have a closed-cell structure, where the pores are not interconnected.The market share between these two types is largely equal.

There are various processing technologies in the production of polyurethane foams. Depending on the properties of the end application, the two most often used at large scale production are moulding and slabstock (block) foaming. Next to these, other prominent types include cavity-filling foam (e.g. car fillings used for acoustic insulation); and spray foam (e.g. roof thermal insulation). These are known as semi-flexible foams behind appropriate overlays.

The flexible polyurethane foam (FPUF) is produced from the reaction of polyols and isocyanates, a process pioneered in 1937.Depending on the application the foam will be used for, a series of additives are necessary to produce high-quality PU foam products. FPUF is a versatile material that can be tailored to exhibit different properties. It allows for superior compression, load-bearing and resilience that provides a cushioning effect. Because of this property, lightweightness, and efficient production process, it is often used in furniture, bedding, automotive seating, athletic equipment, packaging, footwear, and carpets.

Flexible polyurethane foams with a high volume of open pores have been greatly regarded as an effective noise absorption material and are widely used as acoustic insulation in various sectors, from construction to transportation. It is also a very resilient material that does not deteriorate over time and its lifetime is typically linked to the lifetime of the application it is used in.

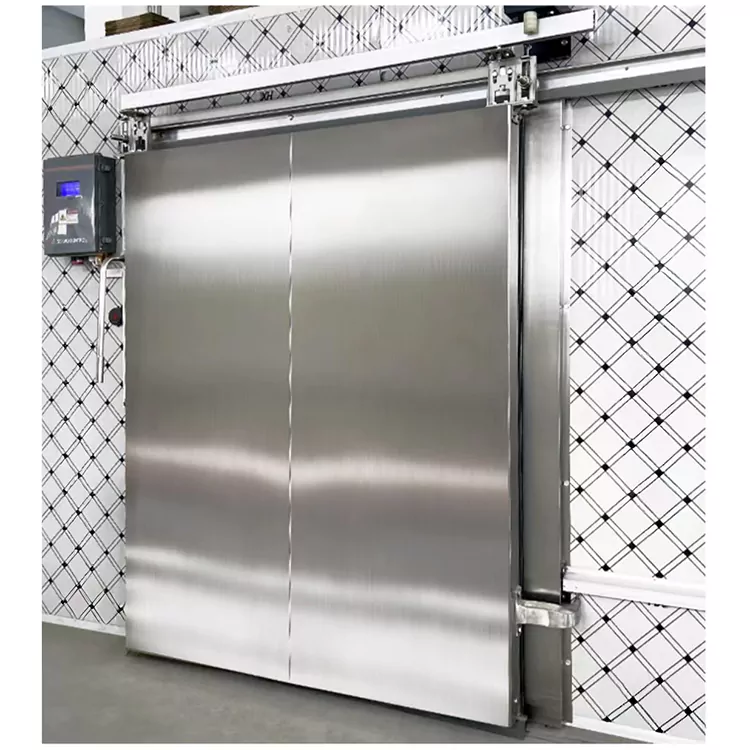

- What Makes a Cold Storage Door Essential for Your Refrigeration Facility?

- Why Are Fully Embedded Cold Storage Doors Transforming the Future of Temperature-Controlled Facilities?

- What Makes Rock Wool Panel a Game Changer in Modern Construction?

- How Does Cold Storage Refrigeration Equipment Improve Food Safety and Efficiency?

- How Do Evaporator Units Improve Cooling Efficiency?

- Why can't cold storage doors be opened from the inside?